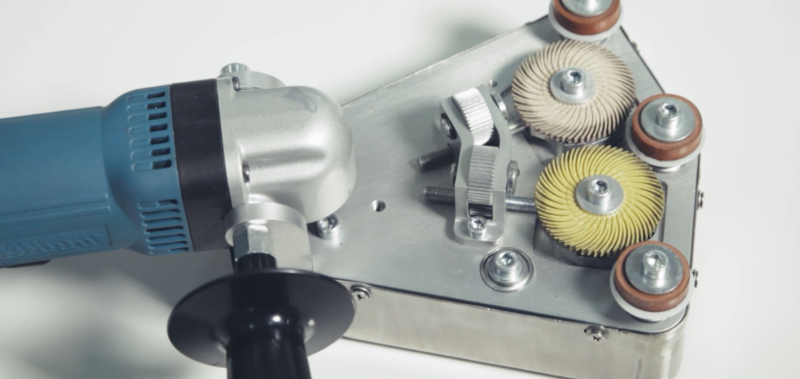

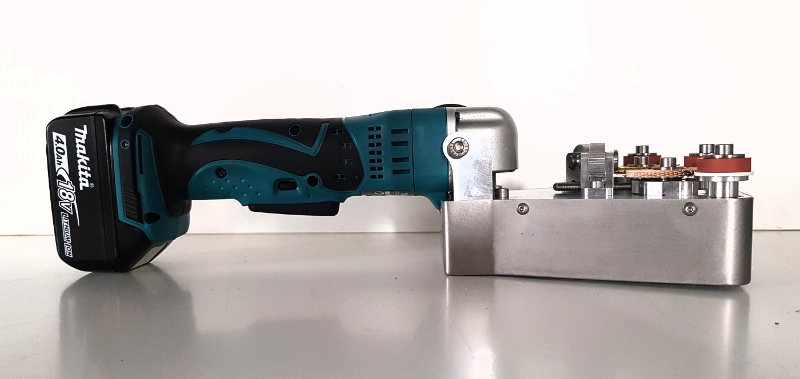

Polish your seaming rolls in 1 minute, without dismantling from the seamers.

SOME OF THE CUSTOMERS WHO HAVE ALREADY TRUSTED US

SEAMING ROLLS POLISHING

TRADITIONAL METHOD

It is necessary to have a large seaming rolls stock

Strechs on the seamer stops due to the seaming rolls polishing

Elevate and expensive dismantling work

It is necessary to have a lathe or engine to polish the seaming rolls, which makes the process more complicated

There is a risk of being caught while the seaming rolls are being polished

It is necessary to have knowledge about the tools to be used and be careful not to damage the seaming rolls

It is necessary a great assembly and adjustment work in the seamers

Work needs to be done by qualified personnel

POLSER POLISHING

It is necessary to have a minimum seaming rolls stock

The stops will be made in minutes or seconds, it will depend on the number of seaming rolls to be polished

No dismantling work is required

It is not necessary to have any large machine, but the seaming rolls polisher

There is no risk of being caught

We will provide you with the necessary work tools and we will advise you about the polisher

No assembly or adjustment work required

The polisher can be used by any operator, it is not necessary to have experience

Our Polser polisher is very versatile

–Suitable for all types of seaming rolls: stainless steel, steel, ceramic, hard metal, etc.

-Suitable for all types of machinery manufacturer, because it fits any seaming roll diameter, regardless of the manufacturer or the seaming rolls measurements and the double seam profile

-Valid for all sectors: food, beverages, animals, painting, aerosols, decoration, etc.

Application for quotes

Request a quote with any commintment, our commercial and sales department is at your disposal QuotesWe look for distributors

We look for national and international distributors, request information with any commitment More